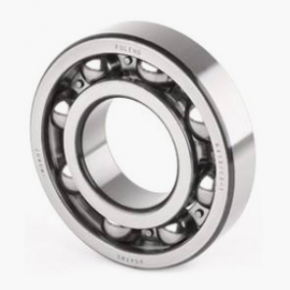

Electrically insulated bearing

The electrically insulated bearing adopts special spraying technology, and high-quality coating is sprayed on the outer surface of the bearing. The coating has strong binding force with the substrate and good insulation performance, which can avoid the electric corrosion of the bearing caused by the induced current, prevent the damage of the current to the lubricating grease, rolling elements and raceways, and improve the service life of the bearing. The process is constantly improved. In the insulated bearing, there is a layer of 100 μ M thick coating that can withstand voltages up to 1000 V DC. The special spraying process can form a layer of coating with uniform thickness and extremely strong adhesion. After further treatment, it can be protected from the influence of moisture and humidity. The electrically insulated bearing can avoid the damage caused by electric corrosion. Therefore, compared with ordinary bearings, it can ensure more reliable operation in the motor. Compared with other insulation methods, such as shaft or shell insulation, it is more cost-effective and reliable. The outline dimensions and basic technical characteristics of insulated bearings are the same as those of non insulated bearings, so they can be 100% interchanged.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mrs Chen

Phone: +1 306-241-5018

E-mail: fengyunc8@gmail.com

Whatsapp:+1 306-241-5018

Add: 210 Maningas Bend,Saskatoon,SK,Canada